Our Philosophy

We believe in handling coal the best way it can be handled, from the first ton out of the mines to the last ton on the ship. With skilled and dedicated employees, state-of-the-art handling systems, superb quality control, a continued commitment to technology and an ideal location, DTA strives for excellence through our founding principles of safety, quality, efficiency and reliability.

A World Class Company

Dominion Terminal Associates, in partnership with Alpha Metallurgical Resources, Inc. and Core Natural Resources, Inc., is a world class coal shipping and storage facility whose team of employees emphasizes safety, quality, efficiency and reliability. We bring high quality metallurgical coal from the mines of Appalachia to our state-of-the-art facility where it is loaded onto ships and barges for customers around the globe. DTA can move up to 22 million tons of coal each year with speed and efficiency.

From Virginia

to the World

Based at the mouth of the James River in Newport News, Virginia, our pier is easily accessible in the port of Hampton Roads, one of the world’s finest harbors, with a dredge-depth of fifty feet, allowing us to ship coal around the World. In 2023, DTA reliably supplied met coal products to customers in twenty-one countries, spanning four continents.

How it Works

01

Our operation begins when coal cars are brought into the facility and positioned on any of our five load tracks, which can hold a total of 500 coal cars.

02

Two cars are separated from the rest of the train and pushed to the dumper. Here, coal is dumped at rates of up to 5200 tons per hour while dust emissions are kept under control by a spray water dust suppression system.

03

Coal then moves up a conveyor belt to a 1000-ton surge silo where it is weighed and sampled for inventory and quality control.

04

Then the coal is moved directly to our pier for ship loading or to our yard stockpiles.

Storing the Coal

When storing, we have two stacker/reclaimers and a third reclaimer, each with travel, luff and slew capabilities. They stack the coal on our sixty-seven acre ground storage yard. The storage area has a 1.7 million-ton capacity. Coal is stacked at a rate of 5900 tons per hour and reclaimed at 6800 tons per hour.

Shipping the Coal

- When coal is scheduled for shipment, two 4000-ton surge silos provide complex, flexible and accurate blending using variable-speed vibrating feeders.

- The coal is weighed on belt scales and sampled by a third party for quality control.

- It is then moved to the shiploader.

- The shiploader can load as much as 6500 tons per hour. It has a 143-foot boom, telescoping chute and rotating spoon, allowing it to reach into the farthest corners of the ship’s holds.

- Our pier has a berth on each side and can handle vessels up to 177 thousand dead-weight tons with up to 79 feet of air draft.

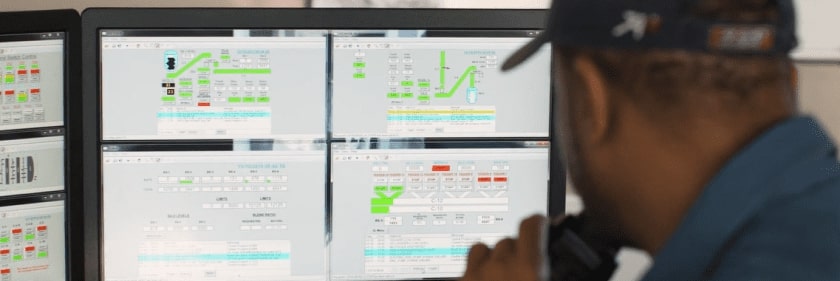

- The entire flow pattern of the coal is monitored, managed and controlled through our computer system. The data collected by this system is available online through the DTA-base app.

Technology Plays a Role

DTA’s commitment to technology also includes a computerized maintenance management system, which helps avoid emergency corrective maintenance. Equipment conditions are consistently monitored using ultrasonic detectors, infrared thermal imaging and vibration analysis. Repairs are completed quickly thanks to our ready inventory of spare parts and ongoing relationship with local suppliers. Combined with a dedicated team, these elements reduce downtime and keep DTA running efficiently.

Terminal Records

In April 1992,

1,037 Cars were dumped in a single day.In March 1987,

123,271 Tons were loaded in a 24-hour period.In 1992,

18,063,519 Tons of coal were handled in a single year.